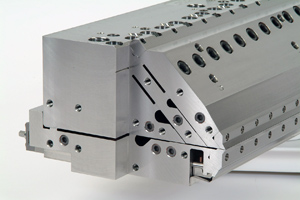

New Coating Die From EDI Is Multi-Manifold

Besides Providing Advantages of Proximity Coating over Roll Coating, Dual- and Triple-Manifold Ultracoat® Dies Replace Multi-Stage Processes with Single-Pass Coating

Chippewa Falls, WI — The first multi-manifold dies for proximity coating of fluids onto web substrates enable converters to use a single die to apply two or more coatings simultaneously, achieving higher productivity than with multi-stage processes and avoiding the oxidation and contamination that coatings undergo between stages, it was announced

by Extrusion Dies Industries, LLC (EDI).

Chippewa Falls, WI — The first multi-manifold dies for proximity coating of fluids onto web substrates enable converters to use a single die to apply two or more coatings simultaneously, achieving higher productivity than with multi-stage processes and avoiding the oxidation and contamination that coatings undergo between stages, it was announced

by Extrusion Dies Industries, LLC (EDI).

EDI disclosed that one manufacturer of high-performance electronic films has already successfully used both dual- and triple-manifold versions of EDI's Ultracoat (R) slot die coating head to apply two and three layers of ceramic slurry to polyester film substrates.

"Slot-die or proximity coating is inherently more efficient and controllable than conventional roll coating because it pre-meters coating fluid at a constant rate and is a fully enclosed system that reduces problems with airborne emissions," said coating-die product manager Jeffrey Seckora. "The development of multi-manifold slot dies adds a whole new dimension to these productivity and quality advantages by enabling converters to apply two or more coatings in one pass."

Other potential applications of multi-manifold Ultracoat dies cited by Seckora are paper coating, in which, for example, a silicone release layer and a pressure-sensitive adhesive are applied at the same time; and application of electrolyte and cathode layers to film batteries.

Key to designing multi-manifold proximity coating dies: achieving laminar flow

A manifold is the flow channel inside the die that distributes the coating

fluid to the desired end-product width, develops a uniform flow pattern, and

establishes the desired thickness. In a dual- or triple-manifold die, the

fluid for each coating

layer undergoes this process within its own manifold before joining with

other coating materials to form a multi-layer structure.

EDI engineers developed successful multi-manifold versions of the Ultracoat system by designing the dies to yield coating streams that exhibit laminar flow, which is flow in which the layers remain distinct after the coating materials combine. "Laminar flow is easier to achieve with viscous fluids, such as the molten polymer streams in plastics coextrusion," Seckora noted. "For the less viscous fluids applied in proximity coating, our engineers designed a streamlined system in which the different layers impinge without turbulence or intermingling of materials."

SOURCE: Extrusion Dies Industries, LLC